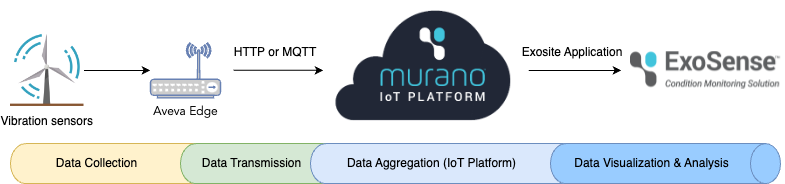

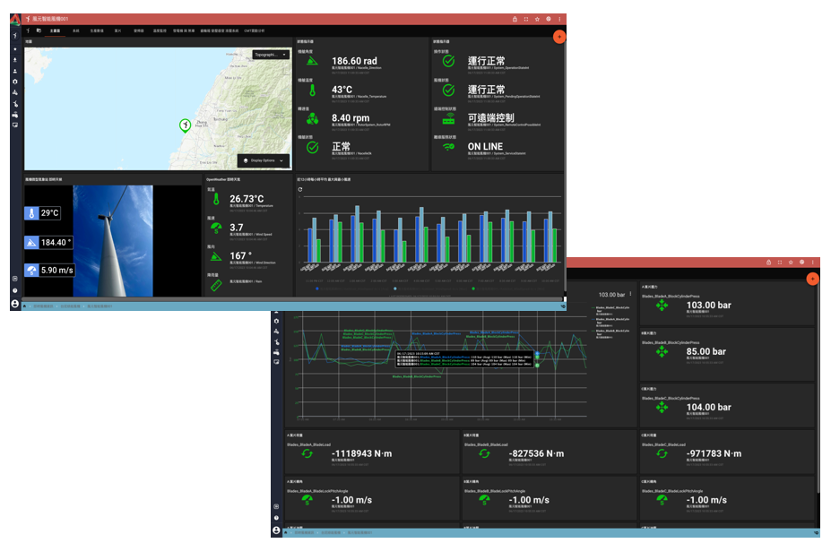

The wind turbine condition monitoring system consists of 8-16 patented vibration sensors placed on the wind turbine's drivetrain. It can monitor the condition of drivetrain components such as the gearbox, generator, and main bearings. Data from these sensors is transmitted over the internet to the ExoSense cloud-based IoT platform, providing real-time data visualization and collection, customized notifications, and anomaly detection for the wind turbines. Through ExoSense, it provides the status of related equipment, allowing for timely maintenance or other contingency measures before damage occurs, thereby preventing a series of accidents that damage might cause.

Please contact First Energy to discuss your requirements.

To sign up, click "Sign Up" and follow the steps to deploy a full solution based on Exosite's ExoSense® cloud application. The software is deployed with a data simulator which helps with configuration and testing prior to hardware installation.

The majority of wind turbine failures happen within the gearbox and generator, leading to costly repairs and downtime. The Condition Monitoring System integrates next-generation of vibration sensor and ExoSense IoT platform to provide an efficient and reliable monitoring system.

The system consists of 8-16 vibration sensors, Aveva Edge SCADA software, and ExoSense condition monitoring system. The vibration sensors are installed on wind turbine drivetrain such as the gearbox, generator, and main bearings. Data from these sensors is transmitted over the internet to ExoSense, providing real-time data visualization, customized notifications, and anomaly detection for the wind turbines.

It is the perfect solution for monitoring land-based and offshore wind turbines, ensuring optimal performance and low maintenance cost in both settings.

To order the system, please contact First Energy.