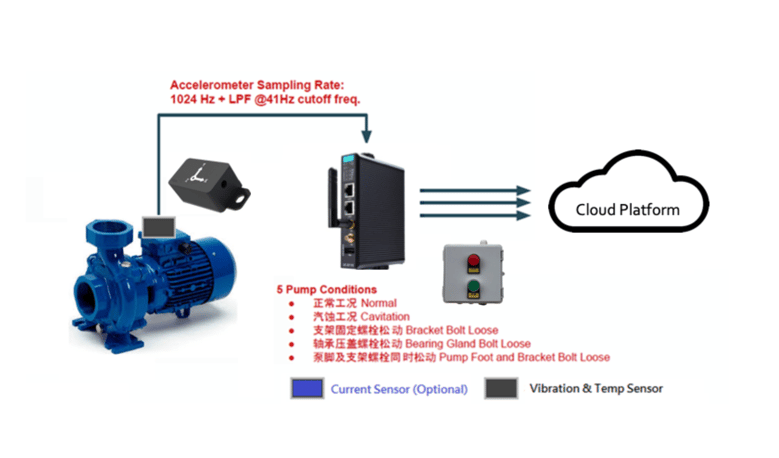

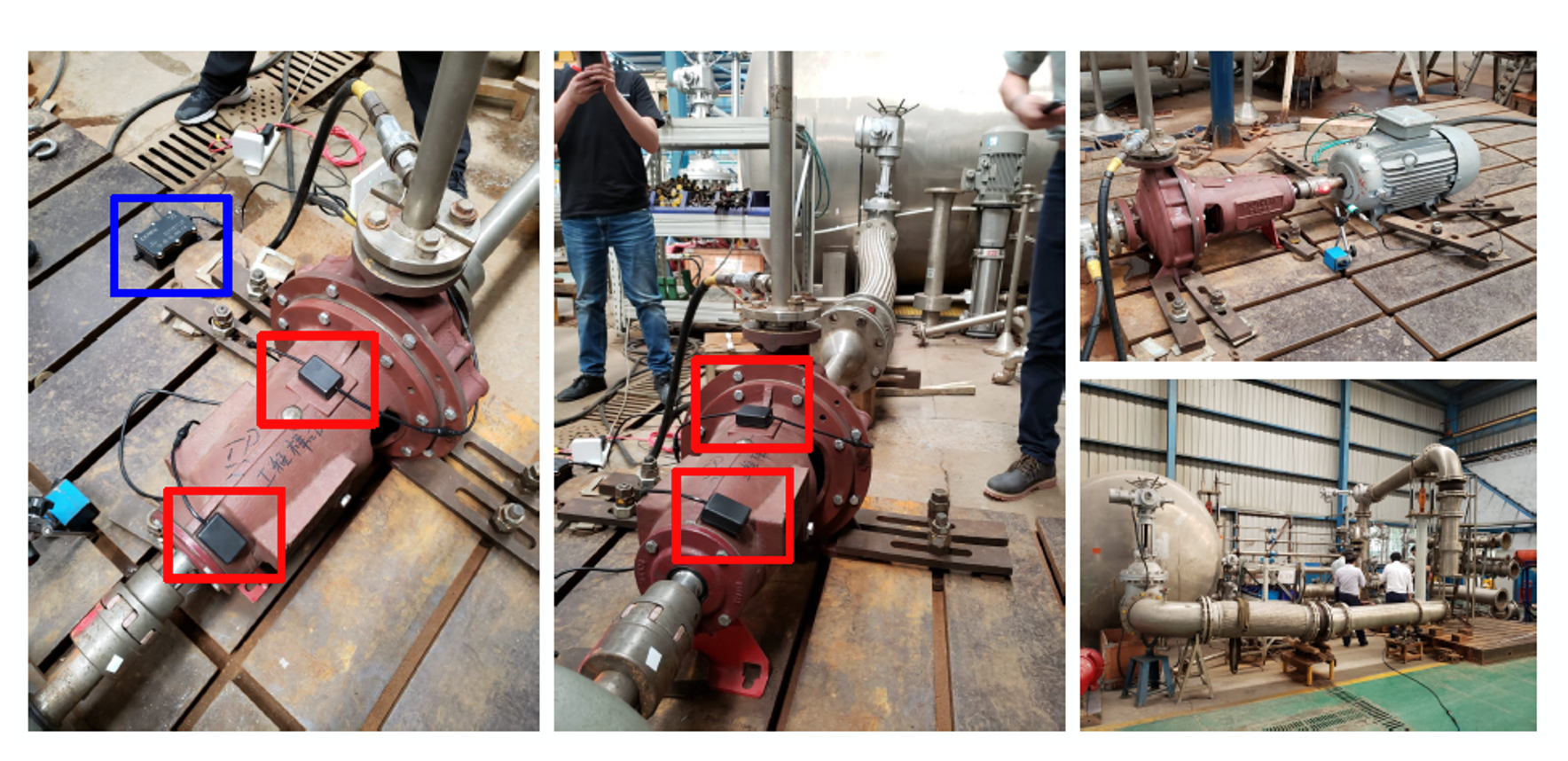

eSol’s Smart Pump Preventive Maintenance solution is a turnkey system that leverages the latest in unsupervised AIoT methods and sensor fusion technology to non-intrusively monitor the real-time and predictive status of pump operation and health.

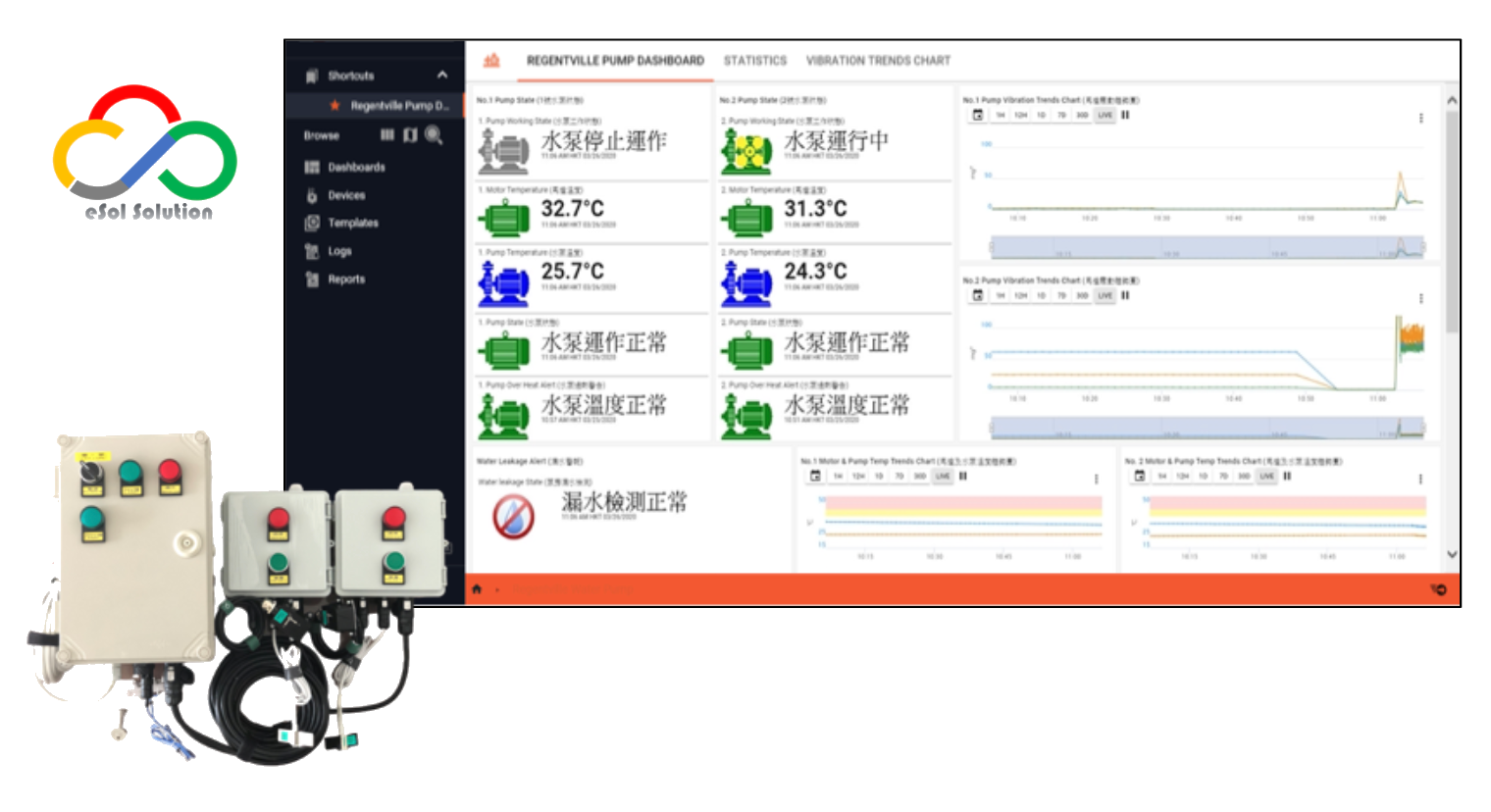

The system is designed for a variety of pumping use cases through the support of an array of sensors including vibration, temperature, current, sound, and other industry-standard sensor outputs. The real time and predictive operating condition of individual pumps, and the pump fleet, is shown on easy-to-use ExoSense dashboards. Data is collected via a 4G network connection and Artificial Intelligence processing is used to establish pump health and to create alerts for potential error conditions.

An optional switch box provides a flexible way to manage switching between primary and backup pumps whenever anomalies are detected. This approach is effective in extending the life of a given pump and to avoid down time in the overall pumping system.

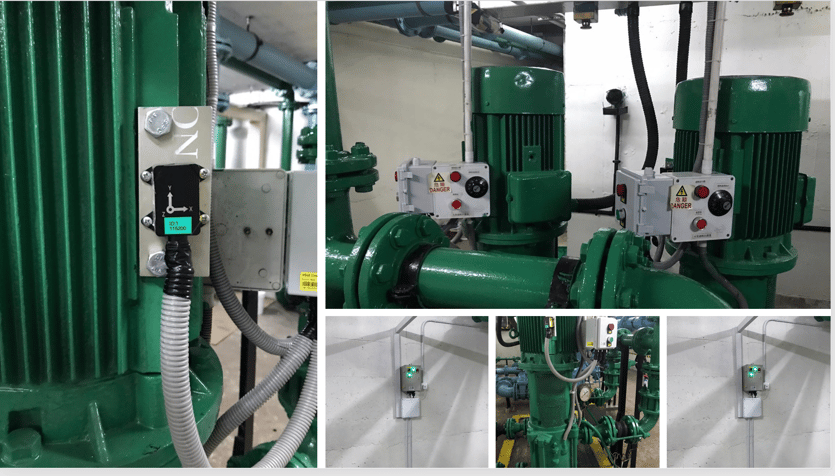

eSol's turnkey approach makes the design and implementation logistics simple.

eSol provides all of the hardware, connections, and telemetry needed to get up and running quickly. Their team comes along side of pump maintenance personnel to design and deploy the system, including providing remote monitoring access to installers, maintenance personnel, and management.

Please contact the eSol support team